Conquering Unwanted Vibration: A Comprehensive Guide to Effective Elim…

페이지 정보

본문

Conquering Unwanted Vibration: A Comprehensive Guide to Effective Elimination

Excessive vibration can compromise the integrity of machinery, diminish operational efficiency, and create uncomfortable or even hazardous working environments. Implementing effective vibration control strategies is essential for maintaining productivity, prolonging equipment lifespan, and ensuring safety.

Understanding the Nature of Vibration

Vibration, in its simplest form, is oscillatory motion around an equilibrium point. This motion can be regular, as in the case of a tuning fork, or complex and unpredictable. Understanding the specific nature of the vibration – its frequency, amplitude, and direction – is crucial for selecting the appropriate mitigation strategy.

Vibrations can originate from a variety of sources, including rotating machinery, impact forces, fluid flow, and even natural phenomena such as earthquakes. Identifying the root cause is the first step towards effective vibration control.

Strategies for Vibration Elimination and Control

Several techniques can be employed to minimize or eliminate unwanted vibrations. These methods can be broadly categorized into source control, path control, and receiver control.

Source Control: Addressing the Root Cause

Source control focuses on minimizing the vibration at its origin. This may involve improving the balance of rotating components, optimizing the design of machinery to reduce inherent vibrations, or selecting equipment with inherently lower vibration levels. Regular maintenance, including lubrication and component replacement, also plays a crucial role in minimizing vibration generation.

Path Control: Interrupting the Transmission of Vibration

If eliminating vibration at the source is impractical or insufficient, path control methods can be implemented to disrupt the transmission of vibration energy. This involves introducing elements into the vibration pathway that absorb or isolate the vibrations. Common examples include vibration isolators, such as rubber mounts or spring dampers, and vibration damping materials, which dissipate vibration energy as heat.

Receiver Control: Protecting Sensitive Equipment and Personnel

Receiver control focuses on protecting sensitive equipment or personnel from the effects of vibration. This may involve isolating sensitive instruments using specialized mounts or providing vibration-reducing hand tools for workers. In some cases, relocation of equipment or personnel away from the vibration source may be necessary.

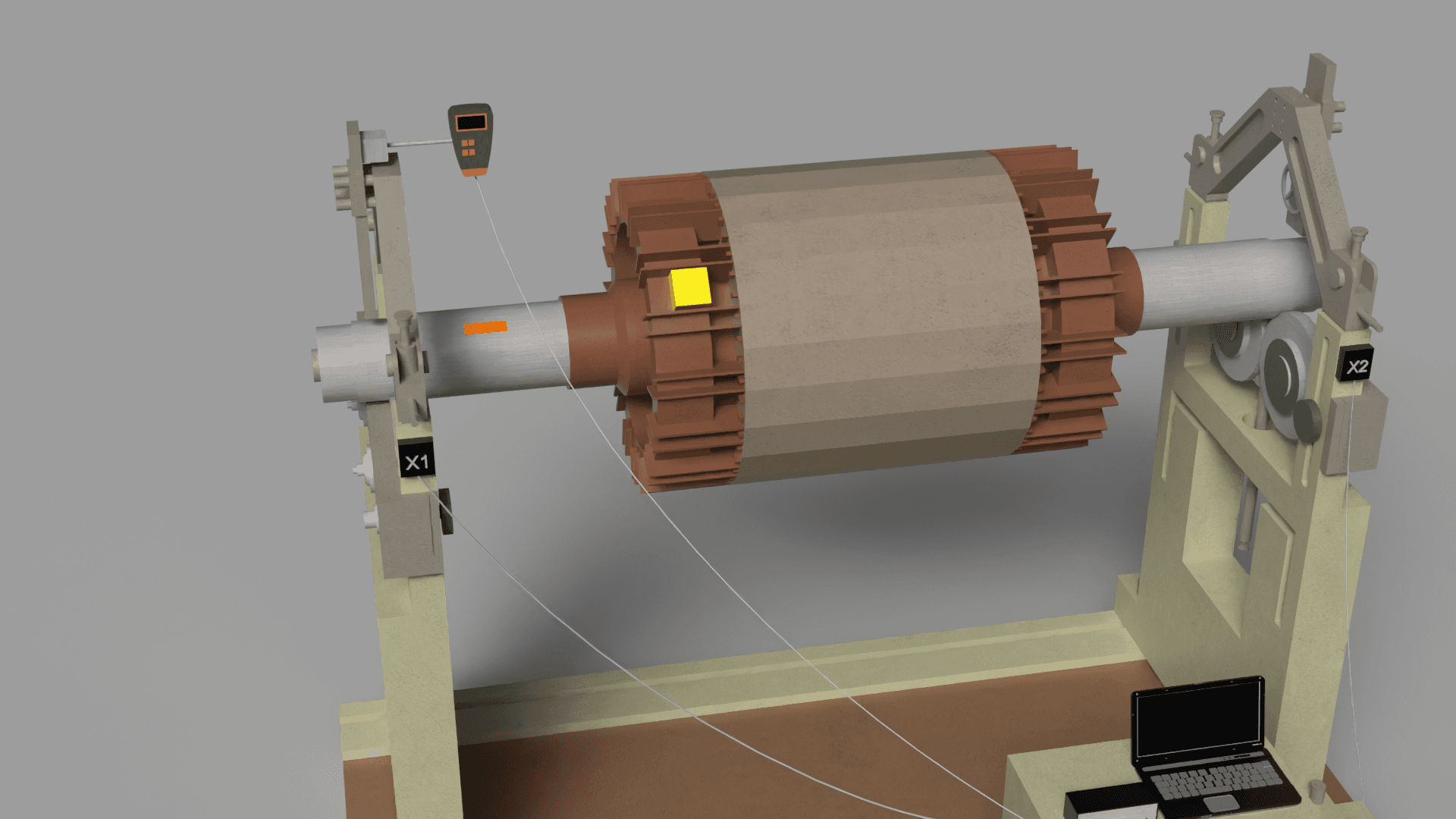

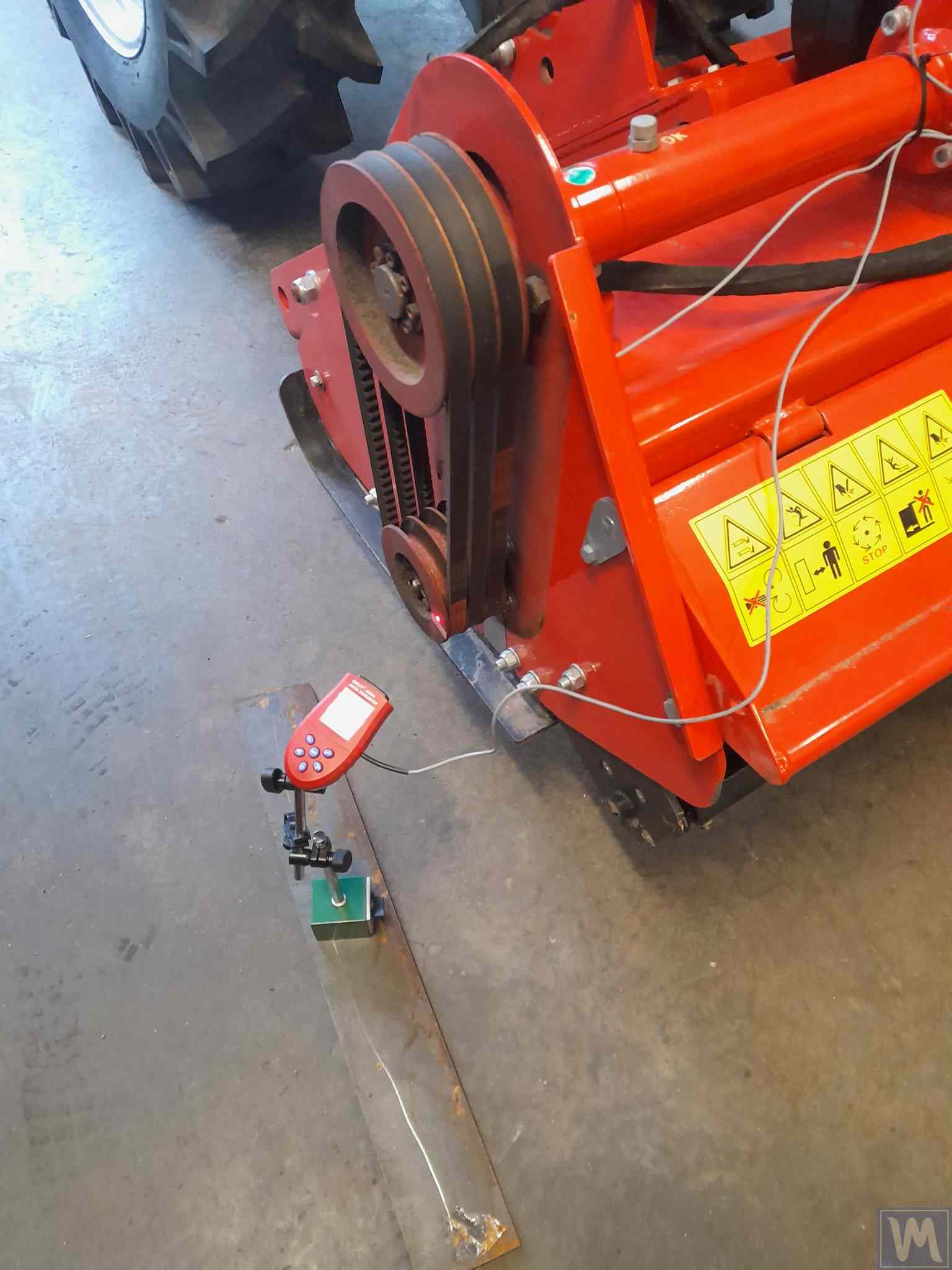

Precision Balancing with Balanset-1A: A Superior Solution

For rotating machinery, imbalance is a primary contributor to excessive vibration. Precise balancing is critical for minimizing vibration and ensuring optimal performance. The Balanset-1A offers a sophisticated solution for dynamic balancing, enabling precise measurement and correction of imbalances in rotors and other rotating components.

The Balanset-1A utilizes advanced algorithms and sensor technology to accurately determine the magnitude and location of imbalances. This allows for precise correction, minimizing vibration and extending the lifespan of rotating equipment. Its intuitive interface and comprehensive functionality make it an invaluable tool for any application requiring precise balancing.

Benefits of Effective Vibration Control

Implementing effective vibration control strategies yields numerous benefits, including:

- Increased equipment lifespan: Reduced vibration minimizes wear and tear on machinery, extending its operational life and reducing maintenance costs.

- Improved product quality: Vibration can negatively impact the precision and quality of manufactured products. Effective vibration control ensures consistent and high-quality output.

- Enhanced worker safety and comfort: Excessive vibration can create uncomfortable and even hazardous working environments. Reducing vibration levels improves worker safety and well-being.

- Reduced noise levels: Vibration often contributes to unwanted noise. Effective vibration control can significantly reduce noise pollution.

- Increased operational efficiency: Vibration can disrupt processes and reduce overall efficiency. By minimizing vibration, operations can run more smoothly and efficiently.

Investing in Vibration Control: A Prudent Decision

Addressing vibration issues proactively is a prudent investment that yields substantial returns. By implementing effective vibration control strategies, businesses can protect their equipment, improve product quality, enhance worker safety, and boost overall operational efficiency.

The Balanset-1A offers a powerful and versatile solution for achieving precise balancing and minimizing vibration in rotating machinery. Its advanced features and user-friendly design make it an ideal choice for a wide range of applications.

Contact us today to learn more about the Balanset-1A and how it can help you conquer unwanted vibration and optimize your operations.

how to eliminate vibration?

- 이전글They Were Requested 3 Questions about 按摩教學... It's A fantastic Lesson 25.02.11

- 다음글Unusual Article Uncovers The Deceptive Practices of 身體按摩課程 25.02.11

댓글목록

등록된 댓글이 없습니다.